Case study NETFrame® – Truck-Axle

Production manager | December 12, 2018

Customer opinion

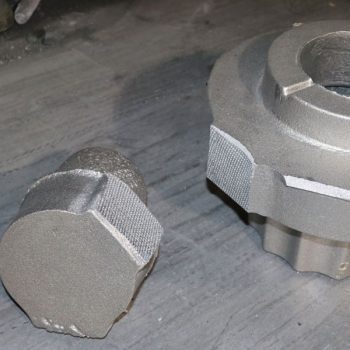

Problem: A large side riser is employed having a contact area of 60 x 120 mm split along the joint line. Due to the size of the contact it is not possible to remove the riser with traditional mechanical means safely without risk of the contact breaking into the casting, meaning that the casting must be transported to a separate work area for riser removal by cutting.

Challenge: Removal of the feeder residue within the regular process, no movement of castings to additional cutting stations.

Axle casting

EN-GJS-400

1.370°C

110 kg

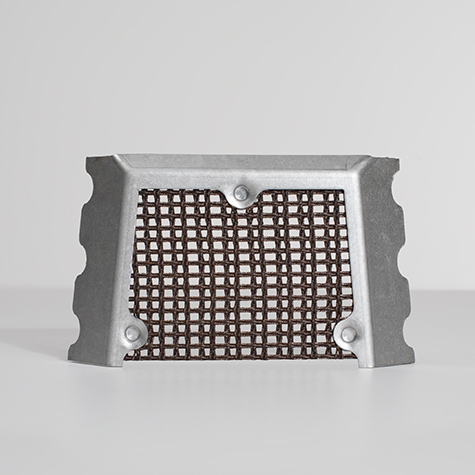

side feeder (see picture)

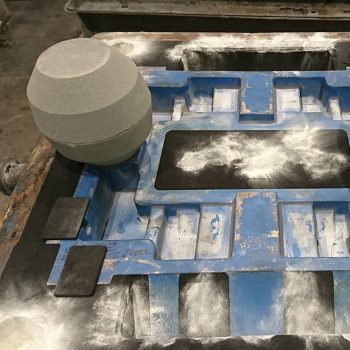

Integration of NETFrame ® technology „NF 1 (53×46)“ into the casting process. The NETFrame ® is placed onto the cope pattern prior to moulding within the riser contact, and against the casting surface.