NETCore® technology was specifically designed and developed for removing high-modulus risers safely and efficiently and subsequently large contact areas on the casting. Traditionally, the removal of these types of risers is facilitated by cutting and grinding, as it is not possible to remove the riser mechanically due to its physical size or without the risk of the contact area breaking into the cast surface upon removal.

Operation

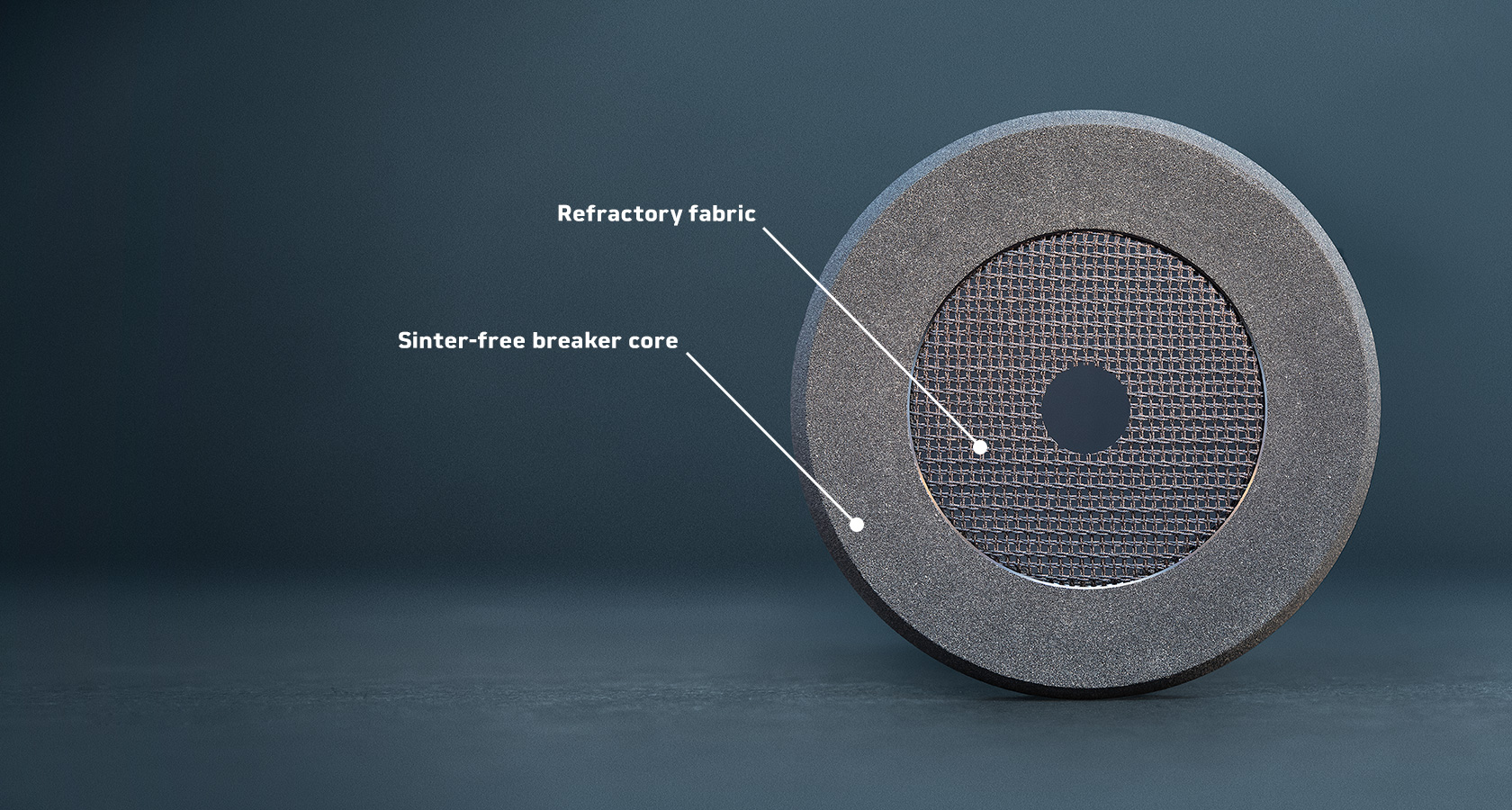

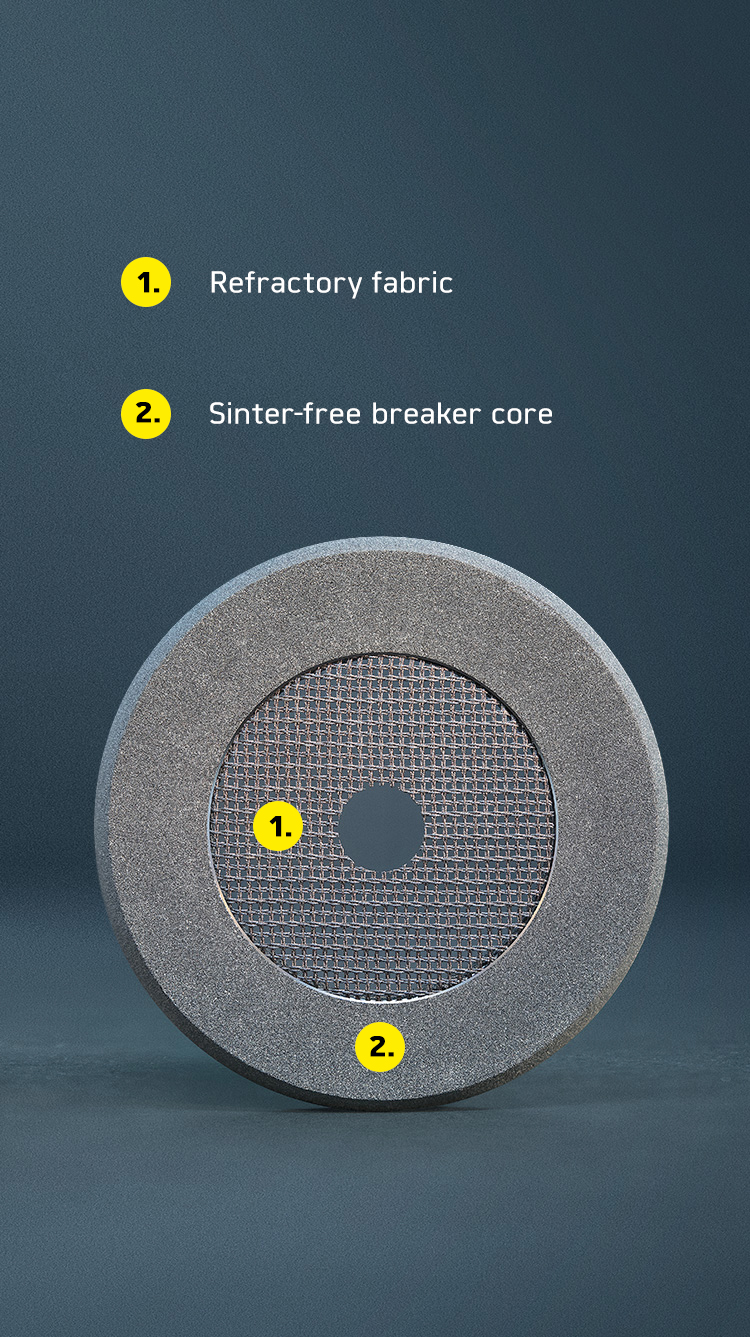

A feature of NETCore® is that the breaker core utilizes a ceramic medium. The high refractoriness offers a significant advantage for preventing metal penetration and distortion, the improved breakdown of the core at shakeout ensures the formation of a clearly defined riser neck. NETCore® has a refractory fabric incorporated in the sinter-free breaker core and where placed, the mesh introduces a clearly defined fracture point within the riser neck, systematically weakening the material at approximately 80% of the cross-sectional area. At this predetermined breaking point, the riser rest can be removed quickly and safely through the formation of a breaking edge “0” at the casting surface.

Case study NETCore® – wind power component (rotor)

“With NETCore®, we can reliably feed particularly difficult-to-access feeder positions and also significantly improve cleaning times and results.”

Gerd Lorenz

Production Manager, HegerGuss

Look at Case Study Download pdf

Case study NETCore® – Frames

“With the utilisation of GTP NETCore® technology we are able to consistently and reliably remove riser residues in hard-to-reach positions in a safe and efficient manner without risk of casting rejection.”

Thomas Windisch

Managing Director, EISENWERK GmbH ELTERLEIN

Look at Case Study Download pdf

Case study NETCore® – Flange

“The use of NETCore®technology enables us to handle very high thermally stressed (thick-walled) components made of GJS within the regular throughput time and without removing the castings from the regular production process. Furthermore, the throughput time in the finishing area is minimized due to greatly reduced grinding work at the feeder neck”

Thomas Zander

Production Manager, GSF FOUNDRY STASSFURT

Look at Case Study Download pdf

Case study NETCore® – scar

“The use of NETCore® technology enables us to manufacture demanding and cleaning-intensive components within the regular lead time without having to deviate from the regular production process. Furthermore, the reject rate is clearly reduced.“

Markus Wellewill

Production Manager

Look at Case Study Download pdf

Advantages of NetCore®

Efficient, precise

removal of risers in perfection

- Reduced cleaning costs

- Faster processing times

- Improved productivity

- Eliminates breaking into the component

- Improved casting surface

- Reduced mechanical load on the component

- Applicable for riser contact diameters up to 450 mm

- Improved process reliability and work safety

A comparison of processing steps

This example calculation shows the time saved by using the NETCore® B250-100 breaker core – feeder neck 100 mm / EN-GJS 400-18LT.

NETCore® starter kit

The NETCore® introductory package/starter kit for extensive use in your foundry is available to order online.

Contents

1 x NETCore®

1 x stopwatch

Order now your NETCore® starter kit free of charge.

Your contact

Jörg Schäfer

Managing Director

As managing director, Jörg Schäfer has headed the company’s sales and technical development since 2006 and is responsible for the development of the new innovative NET-Technology® systems.

Your contact

Nicholas Richardson

Application Technology and Export Sales Manager

As application consultant and responsible for the export business of GTP Schäfer with more than 30 years of experience within the foundry industry, Nicholas Richardson has developed the NET-Technology® in green sand and steel casting.

+90-544-671-3934 / +49-173-520-6937

nicholas.richardson@gtp-schaefer.de

Newsletter

Subscribe to our newsletter and be up to date with our latest in-house developments and innovations.

- © 2026 GTP Schäfer GmbH

- Contact

- Imprint

- Terms and Conditions

- Data Protection