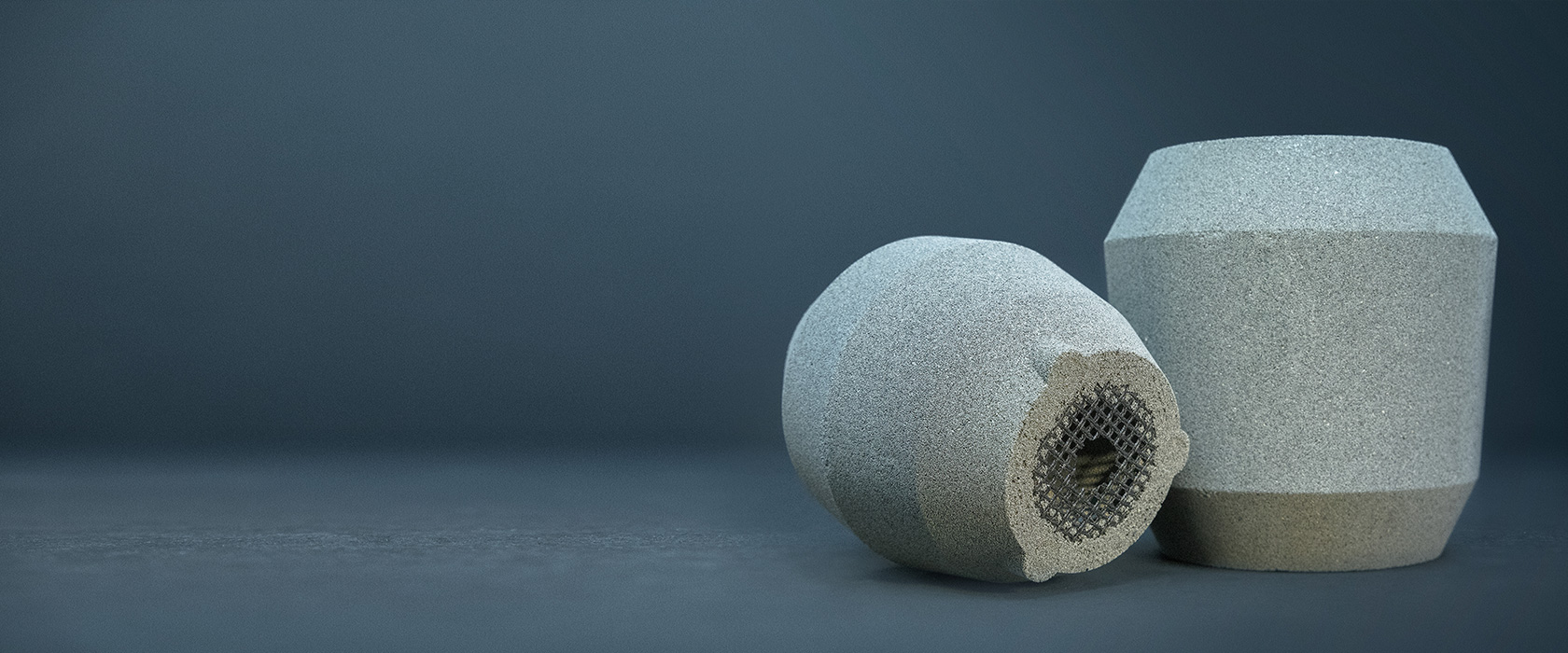

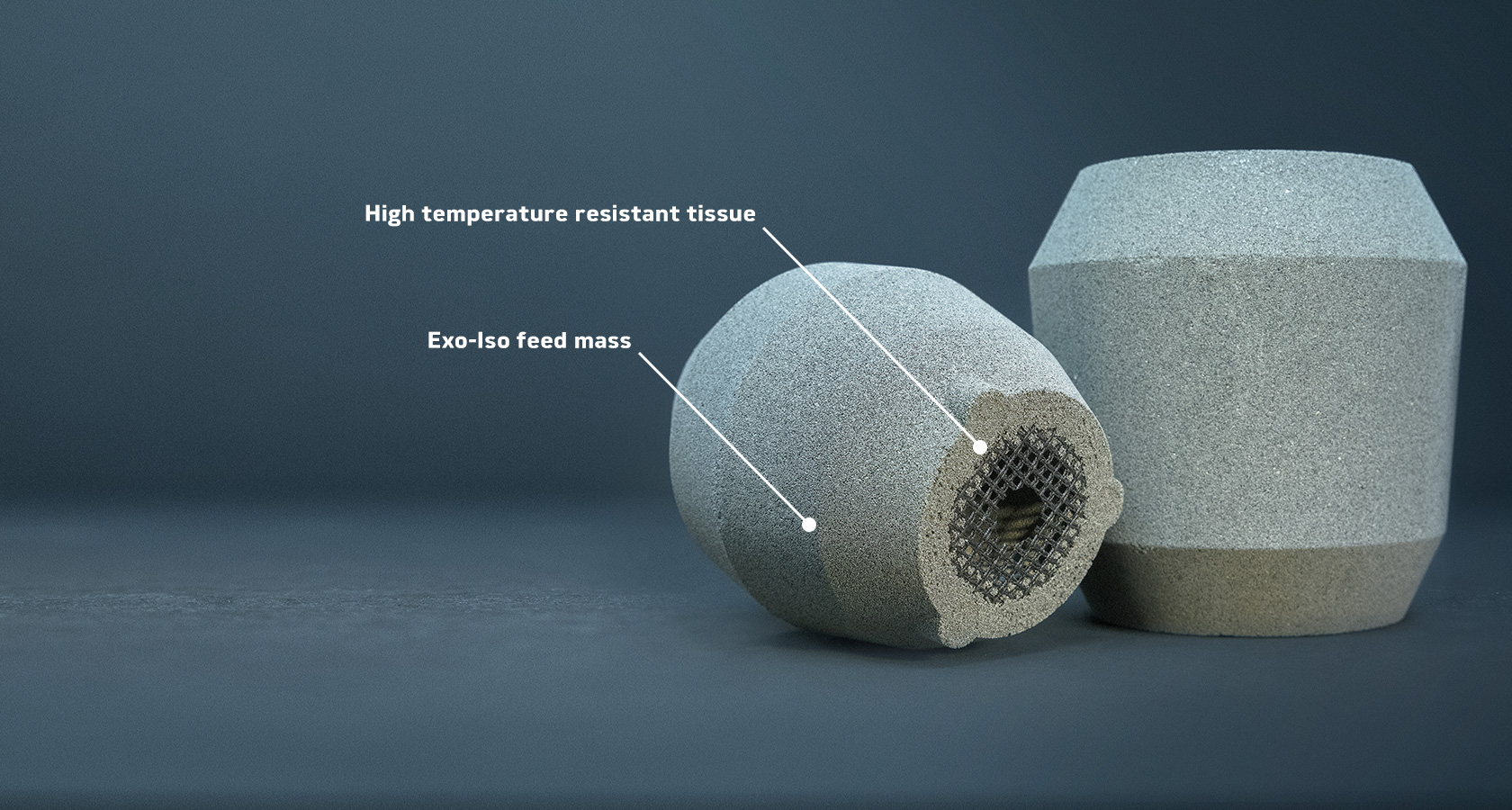

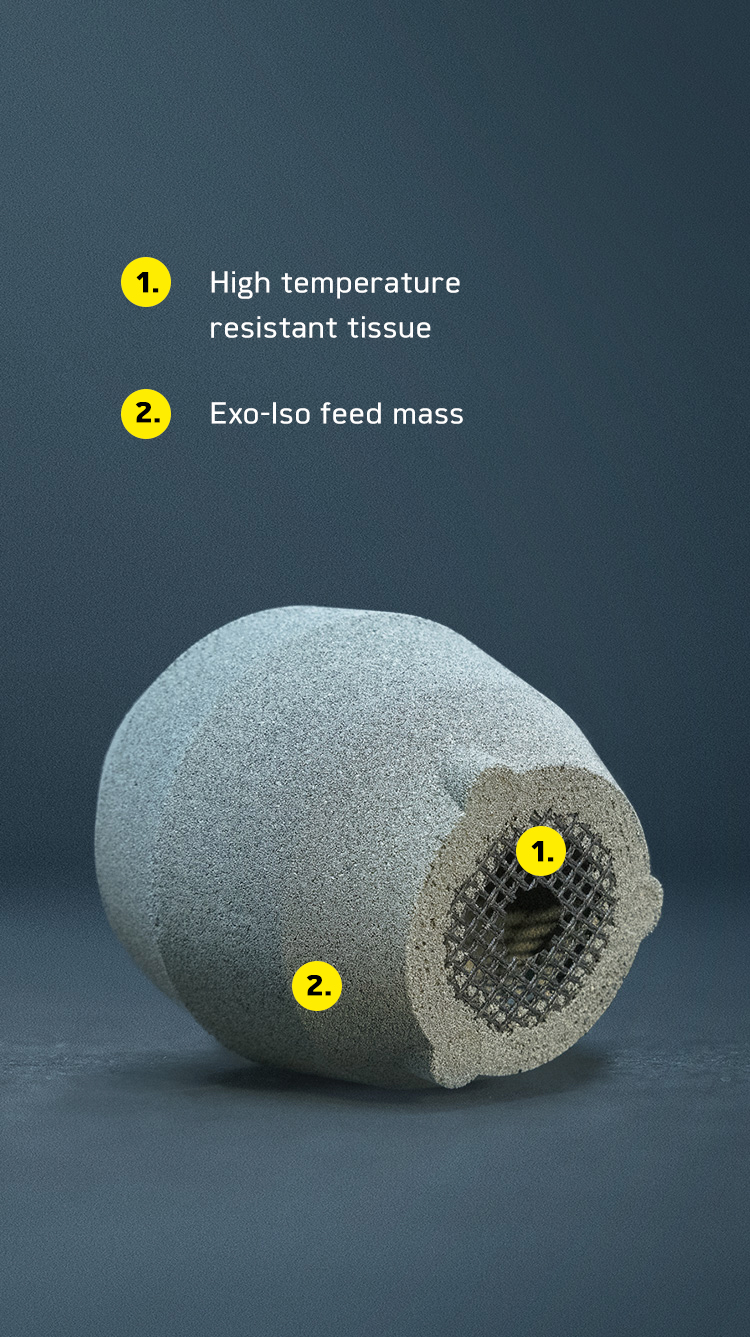

NETSleeve® was specially developed to achieve the largest possible module when using risers or sleeves, without the need for specially designed breaker cores or metal sheets. The technology makes it possible to efficiently remove risers from the casting with a minimum of cutting and grinding.

Operation

NETSleeve® is the successful combination of conventional feeding technology with NET-Technology®. A traditional breaker core or metal sheet used to aid riser removal is replaced with a special refractory mesh, which lies flush to the base of the riser or sleeve. The net ensures a clearly defined, predetermined breaking point directly at riser/casting contact. The mesh systematically weakens the material to approximately 80% of the cross-sectional area, allowing the riser rest to be removed quickly and safely through the formation of a breaking edge “0” at the casting surface with the minimum of force.

Case study NETSleeve® – machine component

“Since the application of NETSleeve® technology in our hand-molding process, the ease with which large castings pass through the cleaning department has improved, with the time taken for riser removal considerably reduced, which has allowed us to increase the throughput of castings by 100%“

Production Manager

Advantages of NETSleeve®

Efficient casting in perfection

- Maximum feeder performance due to lack of constriction

- Risk of early solidification at the riser neck eliminated in comparison to conventional breaker core technology

- Internal geometry shifts the thermal center into the feeder, providing greater feeding reliability

- Efficient and reliable riser removal

- Cleaning costs reduced – cutting and grinding are eliminated

A comparison of processing steps

In this example calculation you can see the time saved by using NETSleeve® TGCN 990o N15 (14 pcs per casting) with a riser contact of 50 mm. The casting material is EN-GJS 400-18LT.

NETSleeve® starter kit

The NETSleeve® introductory package/starter kit for extensive use in your foundry is available to order online.

Contents

1 x NETSleeve®

1 x stopwatch

3 x pins

Order now your NETSleeve® starter kit free of charge.

Your contact

Jörg Schäfer

Managing Director

As managing director, Jörg Schäfer has headed the company’s sales and technical development since 2006 and is responsible for the development of the new innovative NET-Technology® systems.

Your contact

Nicholas Richardson

Application Technology and Export Sales Manager

As application consultant and responsible for the export business of GTP Schäfer with more than 30 years of experience within the foundry industry, Nicholas Richardson has developed the NET-Technology® in green sand and steel casting.

+90-544-671-3934 / +49-173-520-6937

nicholas.richardson@gtp-schaefer.de

Newsletter

Subscribe to our newsletter and be up to date with our latest in-house developments and innovations.

- © 2024 GTP Schäfer GmbH

- Contact

- Imprint

- Terms and Conditions

- Data Protection