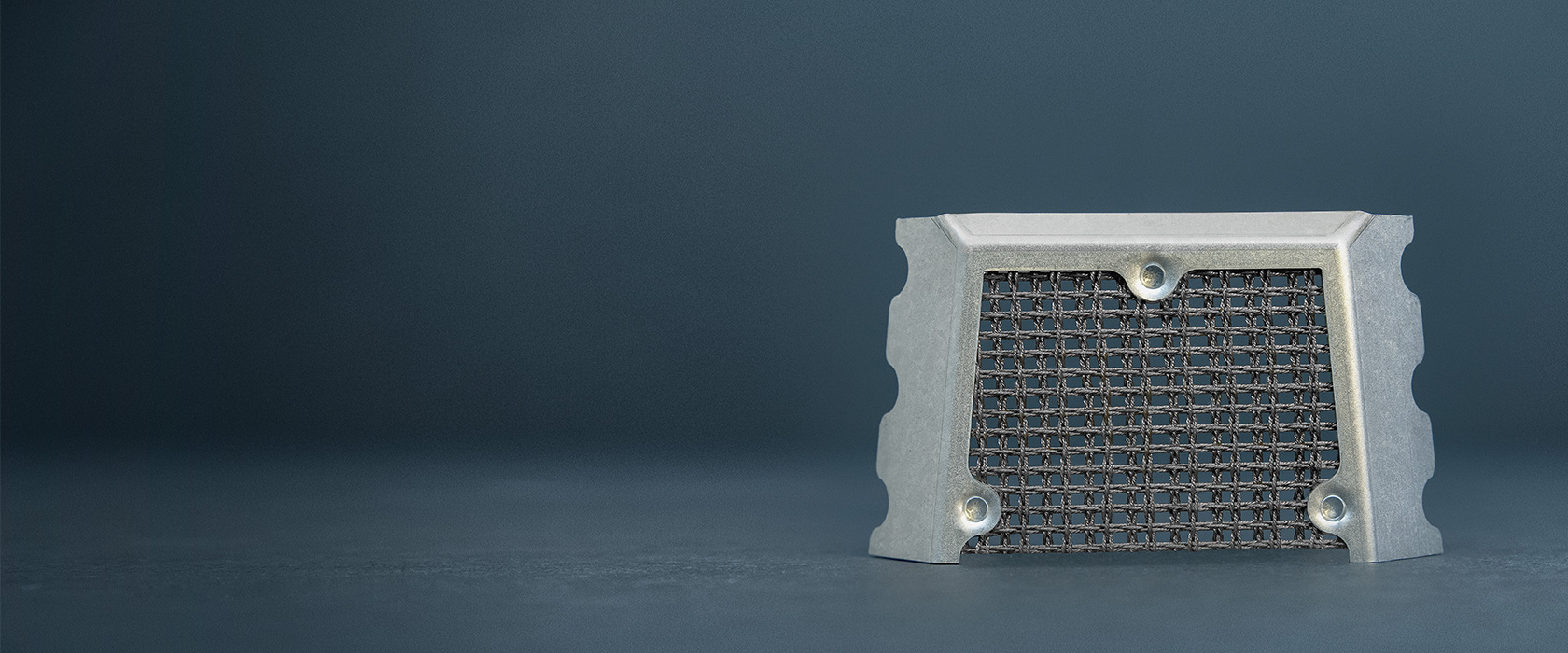

NETFrame® – easy riser removal

The NETFrame® product line was specially developed for the reliable, efficient removal of in-gates

and side riser applications.

Operation

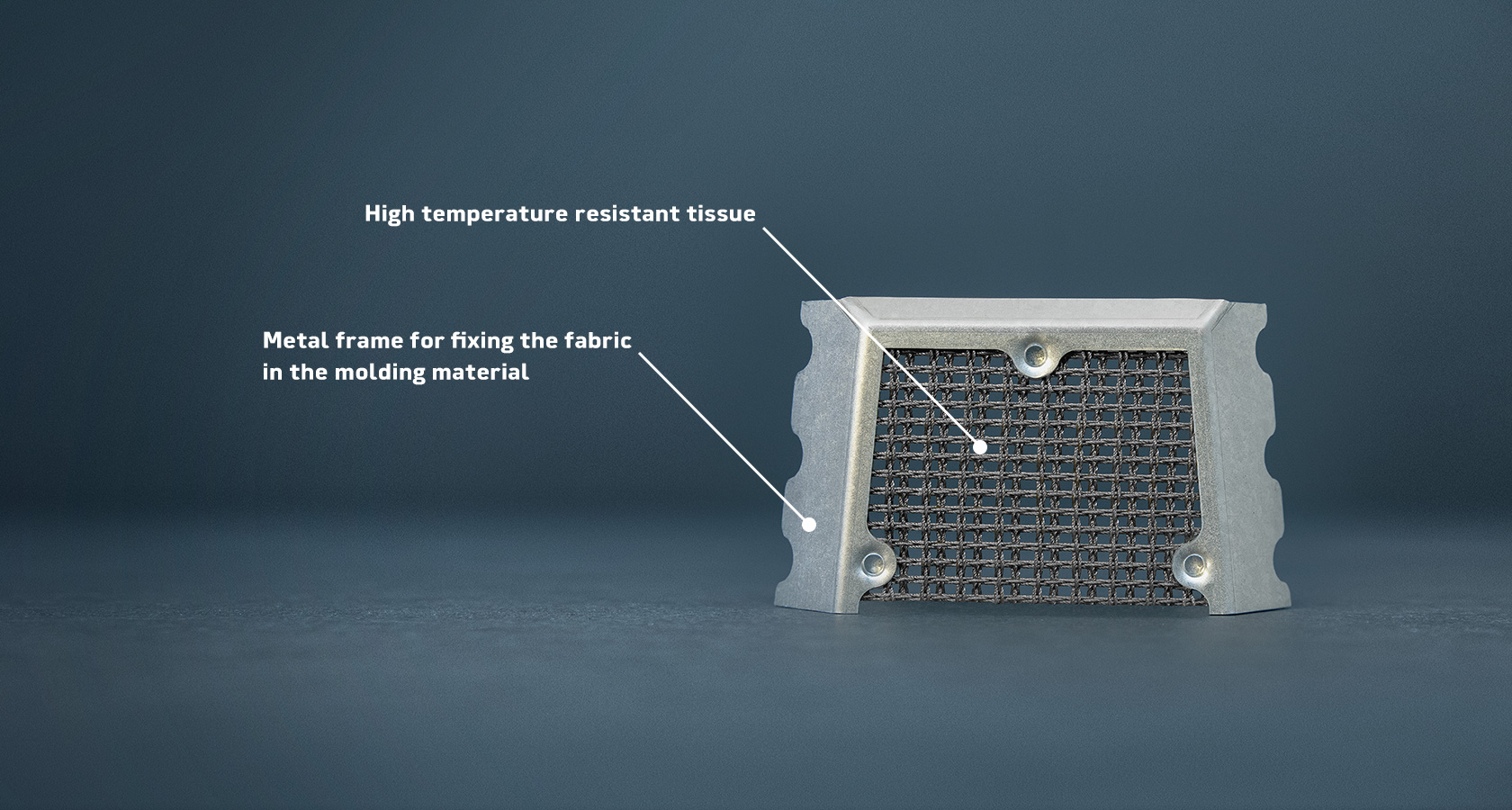

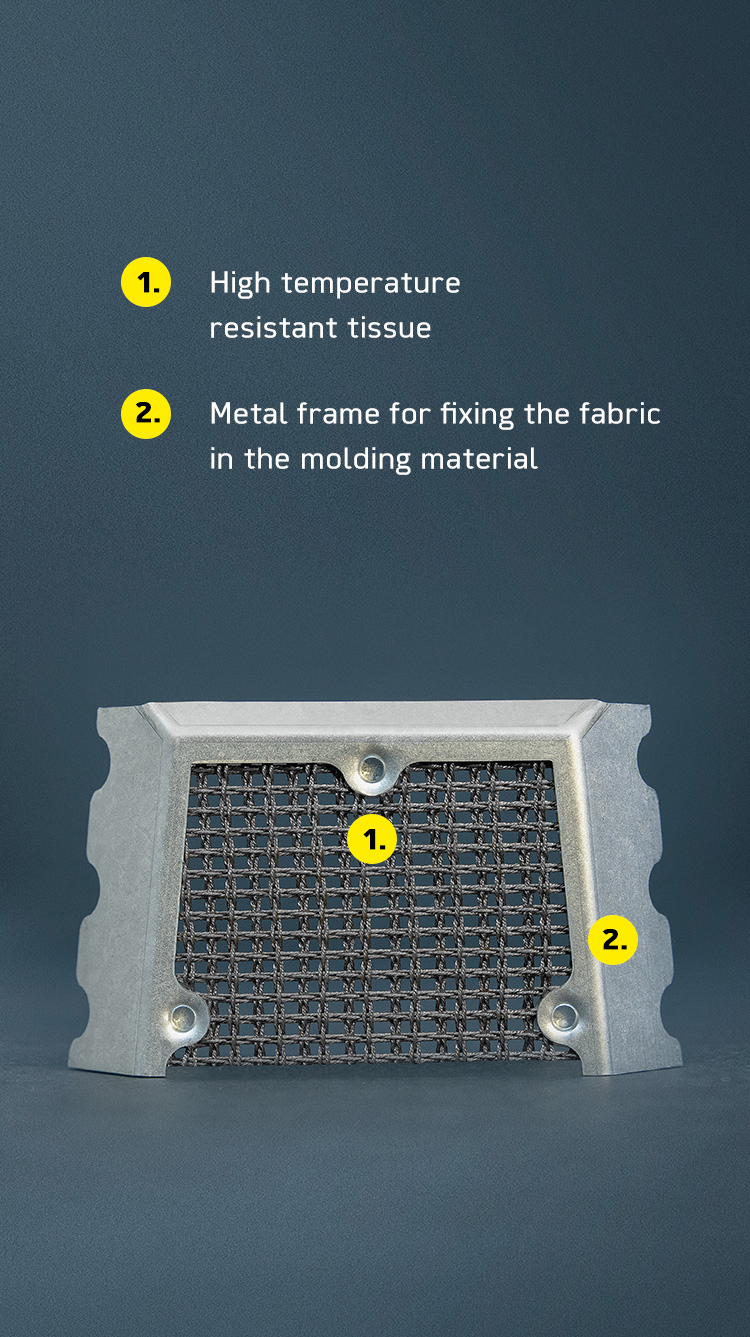

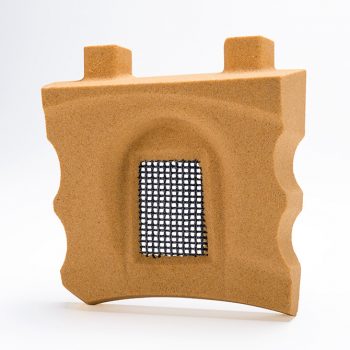

NETFrame® products utilize a high-temperature refractory mesh that is rigidly clamped into a specially designed metal frame. Due to the enhanced shape of the frame, it “grips” into the molding sand and fixes the NETFrame® in the mold, preventing movement, directly at the mold face against the casting surface.

The refractory mesh introduces a cleavage plane within the in-gate or riser neck area, effectively weakening the material. At this predetermined breaking point, the remaining riser or in-gate can be easily and reliably removed with minimal force, improving process efficiency by obviating the need for grinding or cutting.

Case study NETFrame® – hydraulic component

“The NETFrame® technology from GTP Schäfer enables us to significantly reduce our processing times for demanding castings that traditionally involve extended cleaning times. Riser removal is facilitated within the normal process, eliminating the requirement for separate cutting operations. Furthermore, our rejection rate for breaking-in defects has significantly reduced.“

Christian Zouplna

Foundry Manager

Advantages of NETFrame®

Efficient, precise

finishing for perfect castings

- Reliable molding process

- Defined predetermined breaking point directly at the casting surface

- No safety distance between mesh and casting required

- Flexible application with 40–150 mm diameter

- Reduced mechanical load on the components

- Less scrap due to cleaning errors

- process reliability and work safety

A comparison of processing steps

This example calculation shows how much time can be saved by using NETFrame® on the smallest model (NF1 – riser neck 50 x 40 mm).

Application

Introduction of a 2-2.5 mm slot between the casting and the riser neck to accommodate the NETFrame®.

Flexible use of NETFrames on existing pattern equipment.

Reliable shooting into core packages is possible.

NETFrame® starter kit

The NETFrame® introductory package/starter kit for extensive use in your foundry, available to order online.

Contents

20 x NETFrame®

4 x fixing pins

1 x stopwatch

Order now your NETFrame® starter kit free of charge.

Your contact

Jörg Schäfer

Managing Director

As managing director, Jörg Schäfer has headed the company’s sales and technical development since 2006 and is responsible for the development of the new innovative NET-Technology® systems.

Your contact

Nicholas Richardson

Application Technology and Export Sales Manager

As application consultant and responsible for the export business of GTP Schäfer with more than 30 years of experience within the foundry industry, Nicholas Richardson has developed the NET-Technology® in green sand and steel casting.

+90-544-671-3934 / +49-173-520-6937

nicholas.richardson@gtp-schaefer.de

Newsletter

Subscribe to our newsletter and be up to date with our latest in-house developments and innovations.

- © 2024 GTP Schäfer GmbH

- Contact

- Imprint

- Terms and Conditions

- Data Protection