Case study NETFrame® – hydraulic casting

Christian Zouplna, Foundry Manager | May 17, 2019

Customer opinion

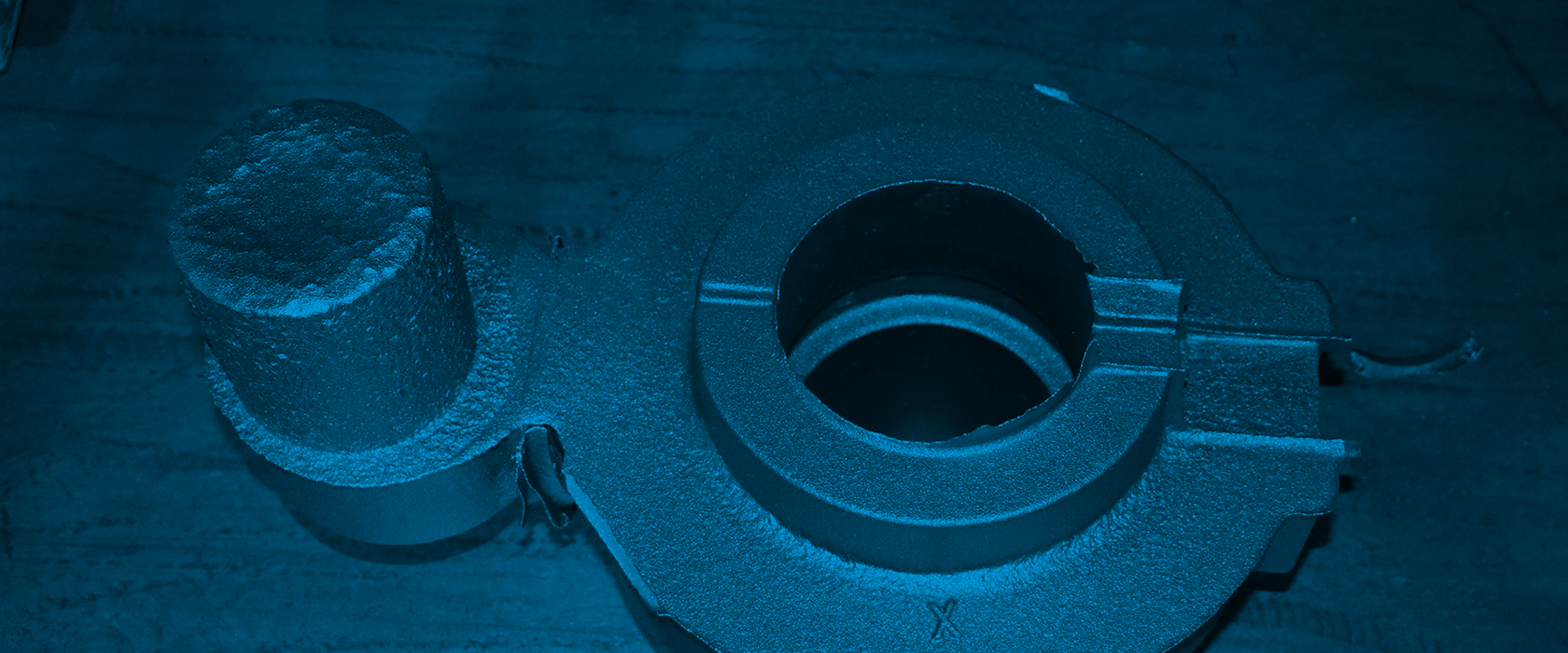

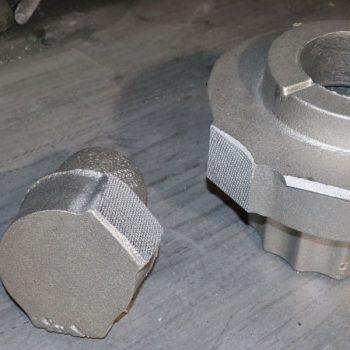

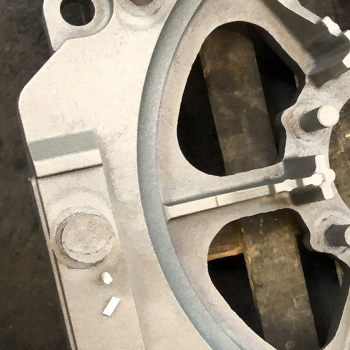

Problem: A large side riser with a contact area of 95 x 75 mm was used. Due to the size of the contact area, it was not possible to remove the riser safely with traditional mechanical means without the risk of the contact breaking into the casting, meaning that the casting had to be transported to a separate work area to remove the riser by cutting.

Challenge: To remove the feeder residue within the regular process without moving the castings to additional cutting stations and without the risk of the riser contact breaking into the casting surface.

SLR Giesserei St. Leon-Rot GmbH

Hydraulic casting

Customer-specific GJS500 – GJS600

75 kg

Two castings on model plate

Side feeder

Integration of NETFrame® technology “NF 120 Special” in the casting process. The NETFrame® is placed onto the cope pattern prior to molding within the riser contact and against the casting surface.