Case study NETSleeve® – machine component

Production Manager | May 05, 2019

Customer opinion

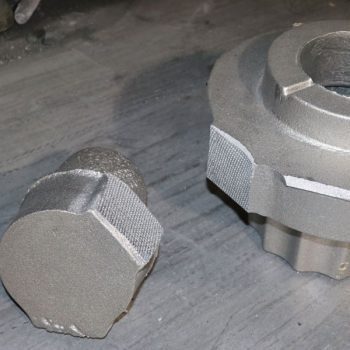

Problem: A variety of mini-risers are used to produce castings with modulus ranging from 1.9 to 3.2 cm without breaker cores and with contacts from 40 to 65 mm. Due to the size of the contact, it is not possible to remove the riser with traditional mechanical means, forcing the foundry to adopt a lengthy cutting process.

Challenge: To efficiently remove the feeder residue by simple mechanical methods and eliminating the lengthy cutting process, allowing the customer to increase the number of castings processed per shift.

Kundengießerei (hand-molding shop)

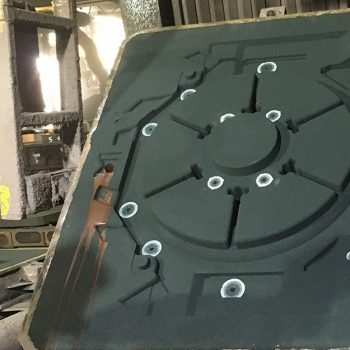

Compressor cover casting

EN-GJS-400 LT18

1,380 °C

135 kg

Thermo risers with modulus 1.9 (x4), 2.1 (x9) and 3.2 (x2) cm

Replacement of traditional risers with NETSleeve® TGC 810o N15, TGC 990o N15, and TGC 2329o N20.