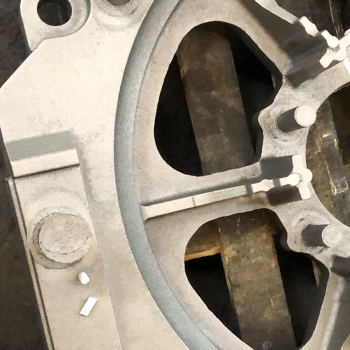

Case study NETCore® – wind power component (rotor)

From Production Manager Gerd Lorenz, HEGER GUSS | May 16, 2019

Customer opinion

Problem: The cleaning times of the component clearly exceeded the desired processing time. Using conventional feeder techniques it was not possible to achieve an improvement on the desired scale.

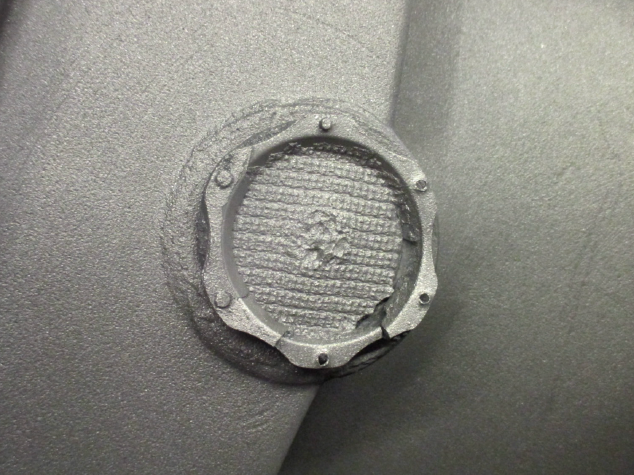

Challange: To reduce cutting time and throughput time for the entire component. Furthermore, the application technology of the component required side feeders on the inside, which could only be removed with great effort.

HegerGuss GmbH

Wind power component (rotor)

EN-GJS- 400-18

1,340 °C

9,800 kg (11,200 kg liquid)

Top feeder and side feeders

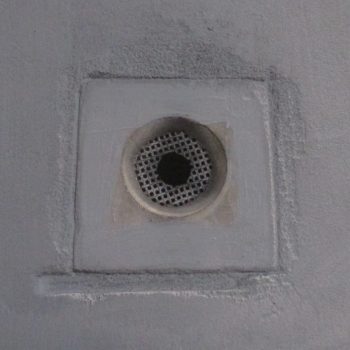

Introduction of NETCore® breaker core technology for top and side feeders