Case study NETCore® – Frames

From Managing Director Thomas Windisch, EISENWERK GmbH ELTERLEIN | March 20, 2020

Customer opinion

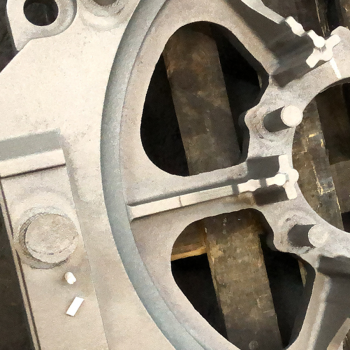

Problem: The knocking-off or separation of the riser residue on the component is not possible, because the size of the feeder neck (80 mm) presents difficulties. Furthermore, there is the risk of breaking into the casting when knocking off. The foundry must remove the remaining riser outside of the regular process in an additional step.

Challange: To remove the riser residue in the regular process without transferring the part to an additional workstation.

Eisenwerk GmbH Elterlein

Frame

EN-GJS-500-7

1.350 °C

1.177 kg

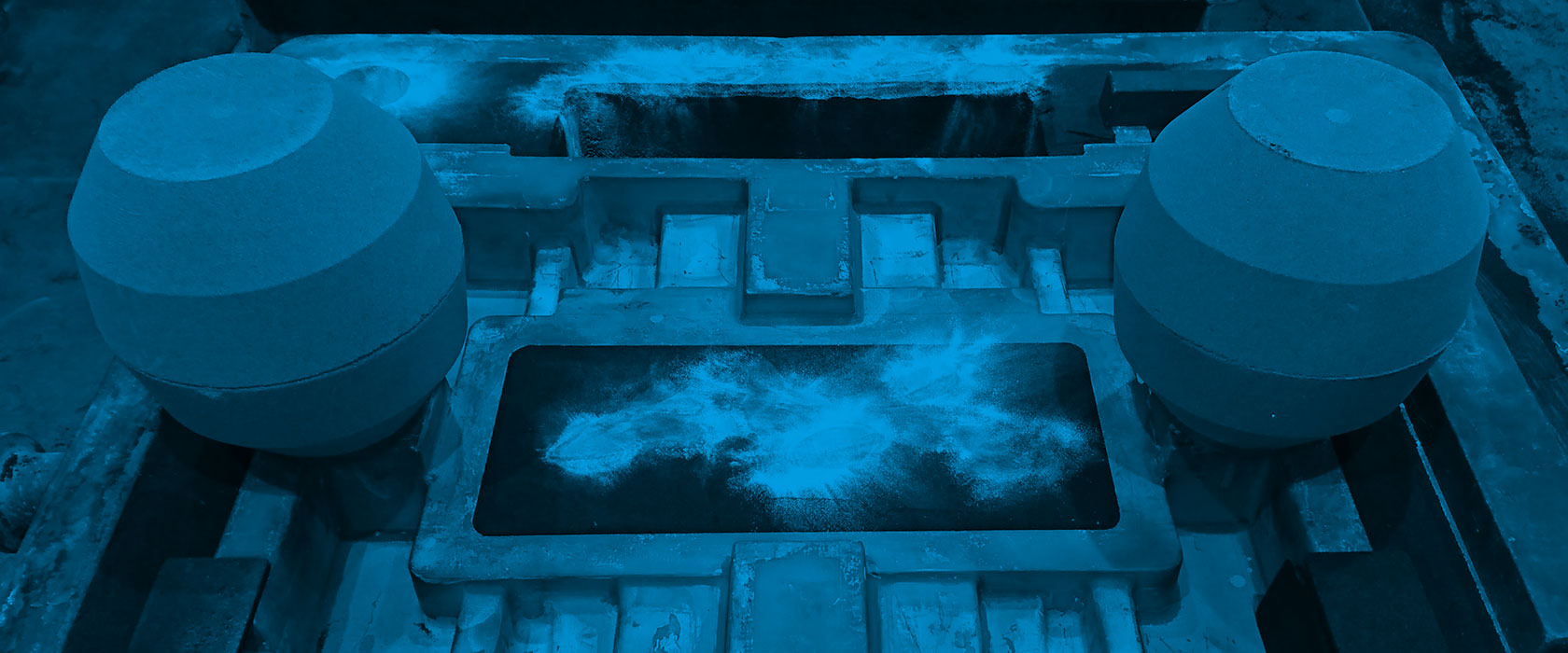

hand moulded

Head feeder

Integration of NETCore® technology on a TG 24000 thermal feeder by a breaker core with NETCore® B 160 – 80 / 20 NR25. TG 24000 B80 NR25.