Case Study NETCore® – HSI scar

From Production Manager Markus Wellewill, FOUNDRY HEUNISCH | March 12, 2020

Customer opinion

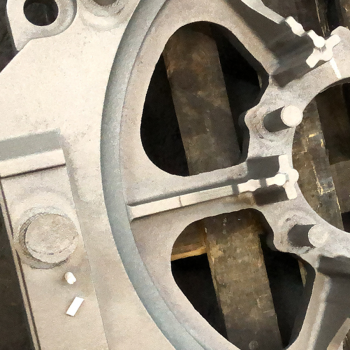

Problem: Due to the large number of risers, the separation of the feeder residues is a very expensive process. In addition, there is the risk of breaking into the casting while knocking off. In the current state, it is necessary to partially remove the risers and the remaining riser attachment is subsequently reworked separately.

Challange: To reduce the work of separation and either reduce or completely avoid riser residues.

Foundry HEUNISCH

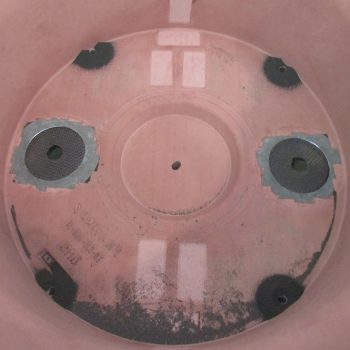

HSI scar

EN-GJS 500-7

7.900 kg

1-hand modell

2 x ZRF 12 B150 NR40

Integration of NETCore® Technology at a fiber feeder